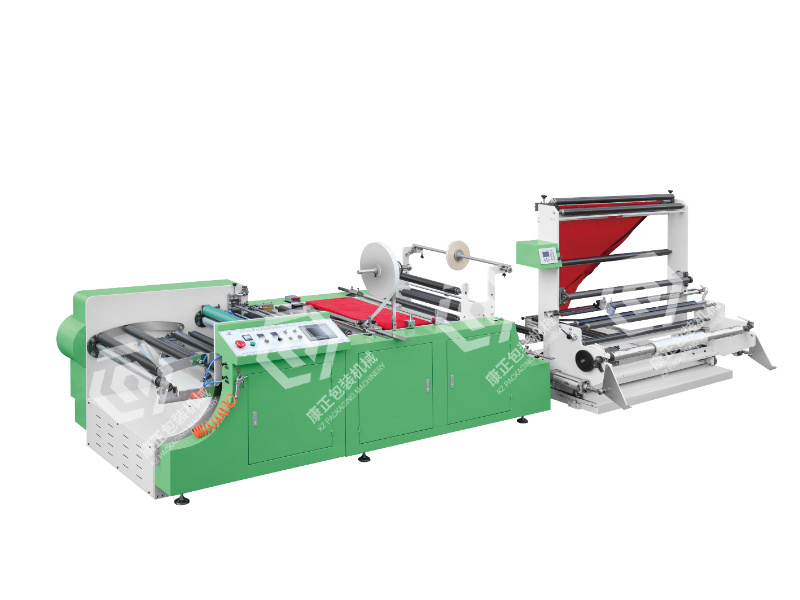

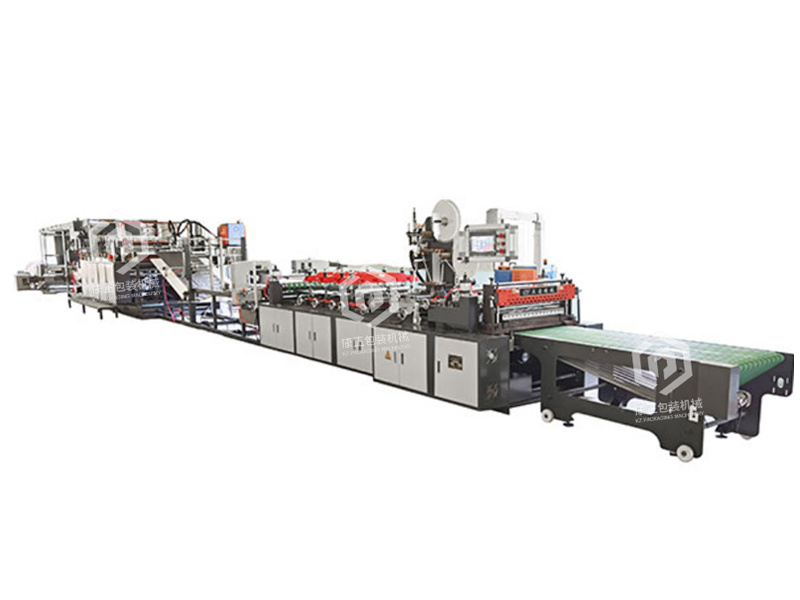

Honeycomb Paper Courier Bag Making Machine

Category:

Note:

1. The face paper material of this machine is all paper. It is better to have (5X40mm) horizontal color mark printed on the paper. If there is no way to print, please suggest.

2. Since the width of the base paper of honeycomb paper cannot exceed 500mm, when making different bag height sizes, only the excess paper on both sides can be overlapped in the middle.

3. The glue used for the second heating and bonding after half-folding must be the glue that does not stick after cooling or air-drying.

Product Description

Precautions:

1. The face paper material of this machine is all paper. It is best to print (5X40mm) horizontal color mark on the paper. If there is no way to print, please suggest.

2. Since the width of the base paper of honeycomb paper cannot exceed 500mm, when making different bag height sizes, only the excess paper on both sides can be overlapped in the middle.

3. The glue used for the second heating and bonding after half-folding must be the glue that does not stick after cooling or air-drying.

一. Brief introduction of machinery:

1. This machine is a bag-making unit specially designed for making bags after kraft paper and honeycomb paper are glued together.

2. Bag making method: fix the kraft paper and the honeycomb paper formed into a honeycomb by stretching on the middle layer of the two layers of kraft paper by spraying glue at a fixed point, and then cut into a strip after the second glue spraying in the transverse direction and fold sealing. Environmentally friendly packaging bags for express delivery with cushioning function.

3. The machine adopts advanced motion control technology. From material unwinding to cutting and forming, all are controlled by computer. The paper bags produced are flat and environmentally friendly, with strong and reliable bonding, simple operation and easy to understand, and are a high-quality machine. Dedicated bag making equipment.

二. Technical parameters:

1. Scope of application: professional production of honeycomb paper core cushion packaging paper bags

2. The highest mechanical speed: 50pcs/min; one big bag, 40 pieces (bag height 500mmX bag width 350mm); one two small bags, 80 pieces (bag height 300mmX bag width 200mm)

(Note: The actual bag making speed will depend on the length of the bag)

3. The maximum bag-making width (the height of the bag):

A maximum bag width (the height of the bag): 550mm (including the tongue of the envelope)

One out two Maximum bag width (the height of the bag): 300mm (including the tongue of the envelope)

4. Maximum bag length (bag width): 450mm

5. Effective unwinding width: paper 1300mmX2, honeycomb paper 550mmX4

6. Effective unwinding diameter: paper 1000mm, honeycomb paper 500mm

7. Mechanical weight:

8. Dimensions: 34mx2.3mx2.4m (length x width x height)

9. Whole machine backup power: 50KW

10.Working voltage: 380V50HZ, three-phase four-wire

11. Main machine steel body

三. The main configuration of the machine (from the direction of the cutter head to the direction of unwinding the material):

(1) Sealing part

1. Master computer

Adopt multi-channel motion controller as the main control of the whole machine, 12 servo control system.

Ten-inch color hanging screen

2. Cutting part

Servo-driven high-speed cutter, stepper motor drives to move forward and backward accurately

3. Sealing knife part

4.4KW high-power servo motor adjusts the speed of the host

After folding in half, the forming and sealing part adopts three heat and one cold mechanical power pressure sealing knife, the width of the sealing knife is 20mm, and the cold pressing knife is a flat knife.

4. Glue part

Since the bag-making method of this machine adopts glue bonding, this machine is equipped with multiple glue spraying stations

(1) Glue spray at the mouth of the bag:

The maximum unwinding diameter of release paper is 500mm, and the diameter of unwinding paper core is 76mm

A set of domestic hot melt glue machine equipment, spray glue at both ends

(2) Horizontal spray glue:

A glue spraying machine is installed on the inclined plate, and a 20mm wide bonding line is sprayed before the material is folded in half. The glue is required to have no stickiness after cooling or air-drying

(2) Fold the forming part in half

Double folding roller type folding rack, which can be folded in one and two in half

(3) Kraft paper unwinding and honeycomb paper lining part

1. The bonding part of honeycomb paper and kraft paper

After longitudinal and transverse positioning spray glue on the outer layer of kraft paper, it is bonded with the stretched honeycomb paper and the inner layer of paper, and then the honeycomb paper material is formed after the fixed point pressing in the longitudinal and transverse directions. At the same time, a servo is also equipped. Motor-driven fixed-length material-drawing nip rollers, two sets of longitudinal and two sets of transverse sealing cold press knife sets.

This part is the core forming part of the machine, which integrates the honeycomb paper stretching device into the honeycomb shape, the vertical and horizontal fixed-point glue spraying device, the positioning and pressing device, and the longitudinal pressing position as an integrated model. Through a computer controller and multiple servos individually controlled, all are fully automatic.

2. Active feeding part

Variable frequency speed regulation and active follow-up feeding, multi-roller surplus swing arm

Feeding speed control adopts domestic frequency conversion speed control, and the feeding motor has a reduction box

3. Four-station unwinding part of honeycomb paper

Maximum unwinding diameter: 500mm

Maximum unwinding width: 550mmX4

Adjustable constant velocity difference honeycomb paper pulling device with bag

4. Kraft paper unwinding part:

Maximum unwinding diameter: 1300mm

Maximum unwinding width: 1300mm

Two-station clamping hydraulic lifting kraft paper unwinding, active constant tension feeding mode, three-inch chuck with bag

(4) Finished product receiving part

Belt-type finished product receiving and conveying platform, 2 meters in length

四. Supporting facilities: (Users are requested to be responsible for themselves)

1. Power supply:

Three-phase five-wire AC 380V 50Hz and grounding wire. (Requirements for the grounding wire: Use steel bars or steel pipes with a diameter of 30-50mm and a length of 1.5m or more to be directly driven into the ground, and a wire of 4 square millimeters at the upper end shall be used.) It is absolutely forbidden to connect the neutral wire to the fuselage.

2. Installation site: The ground hardness is required to ensure that after the equipment is installed and debugged, there will be no foundation settlement during the operation process, which will cause the equipment to operate abnormally or damage the equipment.

3. Air source pressure: constant pressure above 5kg/cm²

4. The whole machine backup power: three-phase five-wire AC, 380V 50Hz, 50KW

5. Commercial matters: (see the purchase and sale contract for details, ten thousand, including tax and freight)

6. Requirements and remarks:

Key words:

Honeycomb Paper Courier Bag Making Machine

Related Products

High-speed Plastic Film Folding ang Winding Machine

This machine is suitable for making high and low pressure vest bags

Automatic high-speed horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

Automatic horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

High-Speed Double Lines Heat Cutting Side Sealing Bag Making Machine

This machine is suitable for making high and low pressure vest bags

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.