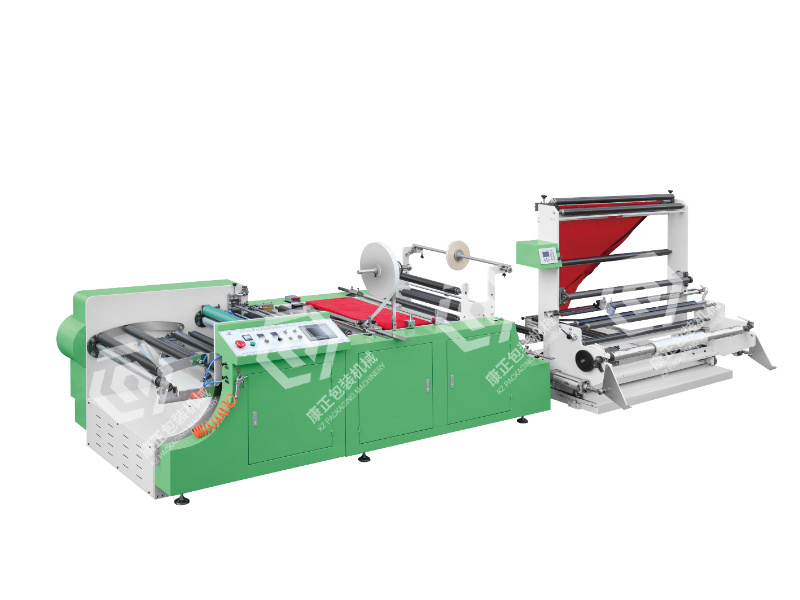

Mid-sealing and bottom-sealing bag making machine (paper bag making machine)

Category:

one. Purpose:

This machine is suitable for cutting various beverage packaging, mineral water label sleeves, wine label bottle sleeves, candy packaging, big cake bags, stickers, paper, etc.

two. Performance and characteristics:

Mid-sealing and bottom-sealing machine (also known as simple three-side sealing) is suitable for automatic middle-sealing, bottom-sealing and cutting of flexible packaging composite bags. The machine adopts microcomputer automatic control, servo motor control, frequency conversion speed regulation, photoelectric tracking, and work counting. , Automatic temperature control, high-position parking, four-iron sealing device, firm sealing, smooth and other technologies. (According to user requirements, punching dies and tear openings, single film bag sealing and cutting devices can be added).

Product Description

一.use:

This machine is suitable for cutting various beverage packaging, mineral water label sleeves, wine label bottle sleeves, candy packaging, big cake bags, stickers, paper, etc.

二. Performance and characteristics:

Mid-sealing and bottom-sealing machine (also known as simple three-side sealing) is suitable for automatic middle-sealing, bottom-sealing and cutting of flexible packaging composite bags. The machine adopts microcomputer automatic control, servo motor control, frequency conversion speed regulation, photoelectric tracking, and work counting. , Automatic temperature control, high-position parking, four-iron sealing device, firm sealing, smooth and other technologies. (According to user requirements, punching dies and tear openings, single film bag sealing and cutting devices can be added).

三. Set configuration

| Mechanical part | Electrical part |

| 1. Unwinding device: the unwinding device adopts magnetic powder and air shaft | 1. The host adopts frequency conversion speed regulation (1.5kw), and the inverter adopts Hualan |

| 2. Frame: adopt steel plate structure | 2. Feeding adopts 1 servo motor (domestic) |

| 3. Cross-cutting tool holder: adopts casting structure | 3. The traction adopts frequency conversion speed regulation 1 |

| 4. Cross-cutting knife: adopt domestic common cutting knife | 4. Double photoelectric tracking and positioning device for edge correction machine (Zhejiang Julong) |

| 5. Drive shaft: slotted with rubber shaft | 5. Independent microcomputer control cabinet: automatic counting, automatic alarm when the number is reached. Automatic shutdown function |

| 6. Hot knife: bottom seal adopts aluminum structure (3 horizontal irons), middle seal hot knife adopts copper structure | 6. Computer (touch screen control) |

| 7. Feeding traction mode: the motor drives the belt pulley to drive the traction rubber shaft | 7. The main engine adopts 1.5KW motor (Shanghai) |

| 8. The maximum substrate width is 700MM, and the longest cutting length is 350MM | 8. Mechanical speed 240 pcs/min |

| 9. The weight of the whole machine is 1500kg | |

| 10. Dimensions: length 5.8 meters * width 1.4 meters * height 1.8 |

Key words:

Mid-sealing and bottom-sealing bag making machine (paper bag making machine)

Related Products

High-speed Plastic Film Folding ang Winding Machine

This machine is suitable for making high and low pressure vest bags

Automatic high-speed horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

Automatic horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

High-Speed Double Lines Heat Cutting Side Sealing Bag Making Machine

This machine is suitable for making high and low pressure vest bags

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.