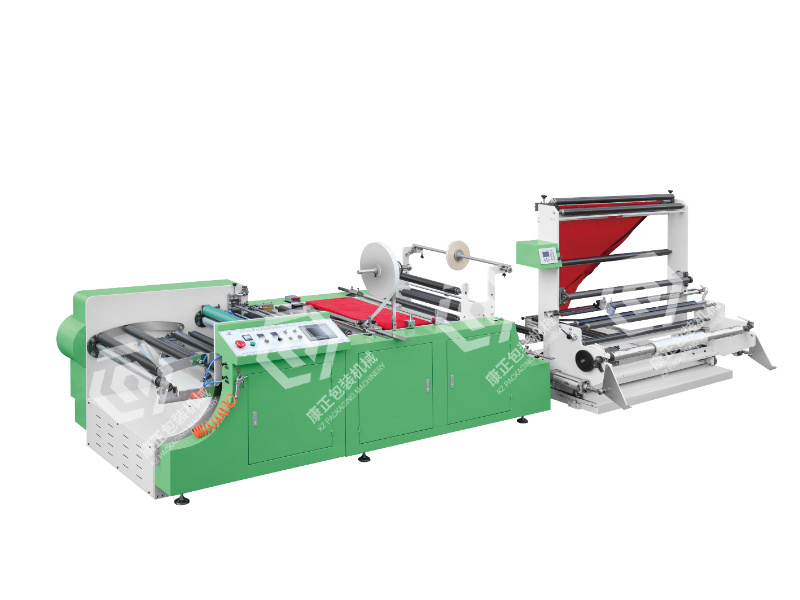

Hot-cut bag making machine (jewelry bag making machine

一. Purpose:

This machine is suitable for eagerly cutting bags of OPP, PP, PE and other printed non-printed plastic film tubes. It is an ideal equipment for making envelope bags, pillowcase bags, clothing bags, towel bags, and jewelry bags.

二. Performance characteristics:

1. The whole machine adopts microcomputer control, frequency conversion speed regulation, and stepping motor to drag the material.

2. Arbitrary fixed length, step-length (servo) photoelectric tracking, accurate and stable, automatic shutdown when the label is lost.

3. Automatic synchronization of double-sided tape, automatic punching, and shutdown when the material is cut off.

4. Heat-sealing lace, automatic constant temperature, firm and smooth sealing.

5. Specially designed for PE tube material, equipped with automatic cutting edge, folding bag opening, inserting the bottom (organ bottom), and hot-pressing shaping functions.

6. Ultrasonic embossing device and pearl film device specially designed for OPP double-folding bags.

7. It can form a complete OPP bag making process with the rectifying and unwinding rack machine.

Product Description

一. Purpose:

This machine is suitable for eagerly cutting bags of OPP, PP, PE and other printed non-printed plastic film tubes. It is an ideal equipment for making envelope bags, pillowcase bags, clothing bags, towel bags, and jewelry bags.

二. Performance characteristics:

1. The whole machine adopts microcomputer control, frequency conversion speed regulation, and stepping motor to drag the material.

2. Arbitrary fixed length, step-length (servo) photoelectric tracking, accurate and stable, automatic shutdown when the label is lost.

3. Automatic synchronization of double-sided tape, automatic punching, and shutdown when the material is cut off.

4. Heat-sealing lace, automatic constant temperature, firm and smooth sealing.

5. Specially designed for PE tube material, equipped with automatic cutting edge, folding bag opening, inserting the bottom (organ bottom), and hot-pressing shaping functions.

6. Ultrasonic embossing device and pearl film device specially designed for OPP double-folding bags.

7. It can form a complete OPP bag making process with the rectifying and unwinding rack machine.

三. Main technical parameters:

| model | DRQ-500 | DRQ-600 | DRQ-700 | DRQ-800 | DRQ-1000 |

| Bag length | 50-700mm | 50-700mm | 60-700mm | 70-700mm | 70-700mm |

| Maximum width of bag making | 500mm | 600mm | 700mm | 800mm | 1000mm |

| Bag making speed | 60-220 PCS/MIN |

60-220 PCS/MIN |

60-220 PCS/MIN |

60-220 PCS/MIN |

60-220 PCS/MIN |

| The widest unwinding of film folding machine | 1150MM | 1150MM | 1350MM | 1550MM | 1950MM |

| Total power | 3.5KW | 4KW | 5KW | 5.5KW | 6KW |

| Machine weight | 1200KG | 1300KG | 1300KG | 1400KG | 1500KG |

| Mechanical Dimensions | 3700×1200 ×1200mm |

3700×1300 ×1200mm |

3700×1400 ×1200mm |

3700×1500 ×1200mm |

3700×1700 ×1200mm |

Key words:

Hot-cut bag making machine (jewelry bag making machine

Related Products

High-speed Plastic Film Folding ang Winding Machine

This machine is suitable for making high and low pressure vest bags

Automatic high-speed horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

Automatic horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

High-Speed Double Lines Heat Cutting Side Sealing Bag Making Machine

This machine is suitable for making high and low pressure vest bags

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.