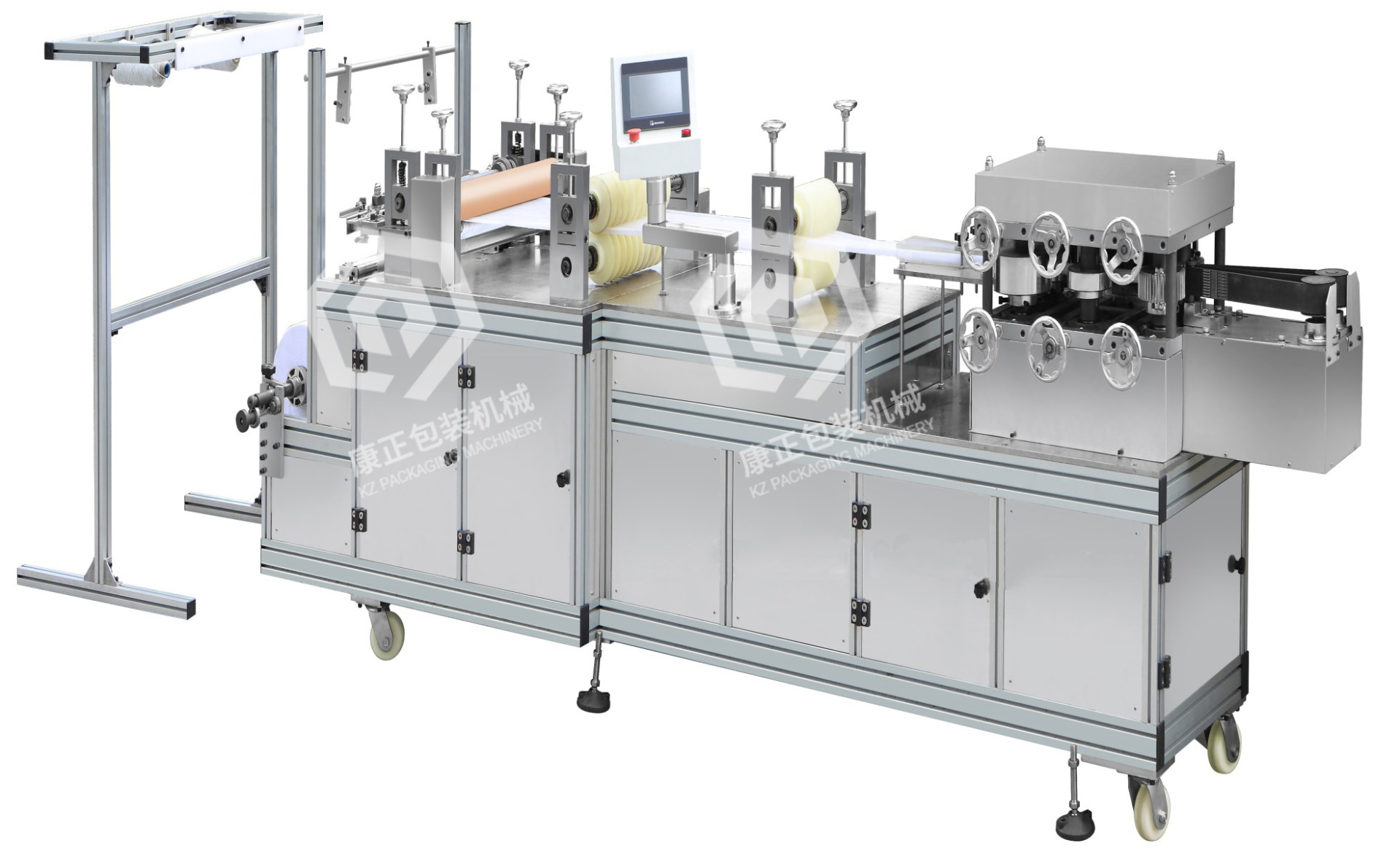

Non-woven strip cap making machine

Performance and characteristics

1. This machine can produce disposable dust-proof strip caps made of plastic/non-woven materials. This machine has the advantages of good quality, low price and high output, saving labor and reducing costs. It can be customized according to customer requirements.

2. This machine is automated. The entire process is automated from the feeding of raw materials to layer products to product counting. Ultra-high-power ultrasonic welding is used to effectively fix both ends of the plastic material or non-woven material and the rubber band. The whole process from the feeding of raw materials to the finished product is automated, and the computer's stepless speed regulation operation is more flexible, and only one person is required for the whole process.

Product Description

Performance and characteristics:

Performance and characteristics:

1. This machine can produce disposable dustproof strip caps made of plastic/non-woven materials. This machine has the advantages of good quality, low price and high output, saving labor and reducing costs. It can be customized according to customer requirements.

2. This machine is automated. The entire process is automated from the feeding of raw materials to layer products to product counting. Ultra-high-power ultrasonic welding is used to effectively fix both ends of the plastic material or non-woven material and the rubber band. The whole process from the feeding of raw materials to the finished product is automated, and the computer's stepless speed regulation operation is more flexible, and only one person is required for the whole process. To

3. Frequency conversion speed regulation.

4. The finished product is delivered when the material is fed.

5. Automatic constant temperature control.

6. High-power ultrasonic welding makes the product more soft and comfortable.

7. The whole machine adopts aluminum parts to make the machine lighter and smoother.

8. With PLC touch screen, data display is clearer.

Craft:

The equipment adopts ultrasonic method and frequency conversion speed regulation to produce disposable dust-proof strip caps of plastic and non-woven materials from feeding to finished products to complete integrated production. To

Production Process:

Automatic feeding-import-folding-welding-forming and cutting

To

Main features of the machine:

1. Disposable caps used to make plastic and non-woven fabrics

2. The staff is easy to operate

3. Advanced ultrasonic welding technology

4. Stable performance, low failure rate

5. One operator can run 2 machines at a time

6. Adjustable frequency and speed

7. Low working noise and small area occupied by the machine

MAIN TECHNICAL PARAMETERS

| model | Model-YMJ |

| Machine size | 3800×900×1300mm (length*width*height) |

| Outer packaging size | 3900×1000×1550mm (length*width*height) |

| Output | 100-180 pcs/min |

| Product size | 19 inches |

| Voltage | 220v 60HZ |

| Number of Ultrasonic Units | 3 Sets |

| Power consumption | 4.5KW |

| Machine heating power | 5 KW |

| Machine net weight | 825KG |

| Machine gross weight | 1055KG |

Key words:

Non-woven strip cap making machine

Related Products

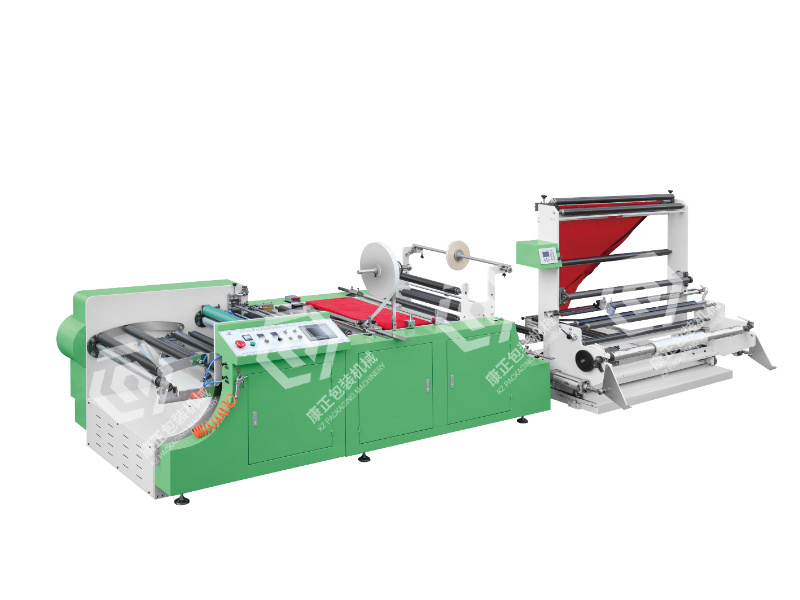

High-speed Plastic Film Folding ang Winding Machine

This machine is suitable for making high and low pressure vest bags

Automatic high-speed horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

Automatic horizontal slitting machine

This machine is suitable for making high and low pressure vest bags

High-Speed Double Lines Heat Cutting Side Sealing Bag Making Machine

This machine is suitable for making high and low pressure vest bags

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.